Maximizing Potential with Test Fits

In the fast-paced world of industrial development, time and money are precious commodities. Yet, it can be easy to overlook a critical step that can save both: the test fit process. Chris Westbrook, PE, a Senior Program Director in our Industrial Business Unit, shares how we leverage this crucial planning tool to assist clients in ensuring project feasibility and regulatory compliance and optimizing site layout, infrastructure planning, and cost estimation. By undertaking a comprehensive test fit, industrial developers can mitigate risks, enhance decision-making, and ultimately protect their bottom line.

Civil engineers understand the complexities and challenges of industrial

development projects. The test fit process is an indispensable part of our

toolkit, offering numerous benefits to developers:

Feasibility Assessment

Test fits provide a preliminary evaluation of whether a proposed industrial development can be feasibly accommodated on a specific site. This includes checking if the property can support the desired building footprint, parking, and other site elements. By conducting this assessment early, it becomes easier to address potential challenges before advancing further in the project.

Optimization of Site Layout

By conducting a test fit, we can optimize the site's layout, ensuring efficient use of space while meeting regulatory requirements and the developer's needs. This can involve configuring building layouts, access points, parking lots, and stormwater basins to maximize functionality and cost-effectiveness. An optimized layout not only saves space but also enhances the project's overall efficiency.

Regulatory Compliance

Test fits help identify potential compliance issues with local zoning codes and environmental regulations early in the planning process. Taking this proactive approach reduces the risk of costly redesigns and delays later. Early detection and resolution of compliance issues are critical to keeping the project on schedule and within budget.

Financial Planning

The test fit process provides a clearer picture of key cost drivers, such as significant grading, retaining walls, site access improvements, and other civil engineering site work, helping developers budget more effectively. These insights help developers more accurately estimate development costs. This early phase can help align high-level financial expectations with site realities and support better financial planning.

Risk Mitigation

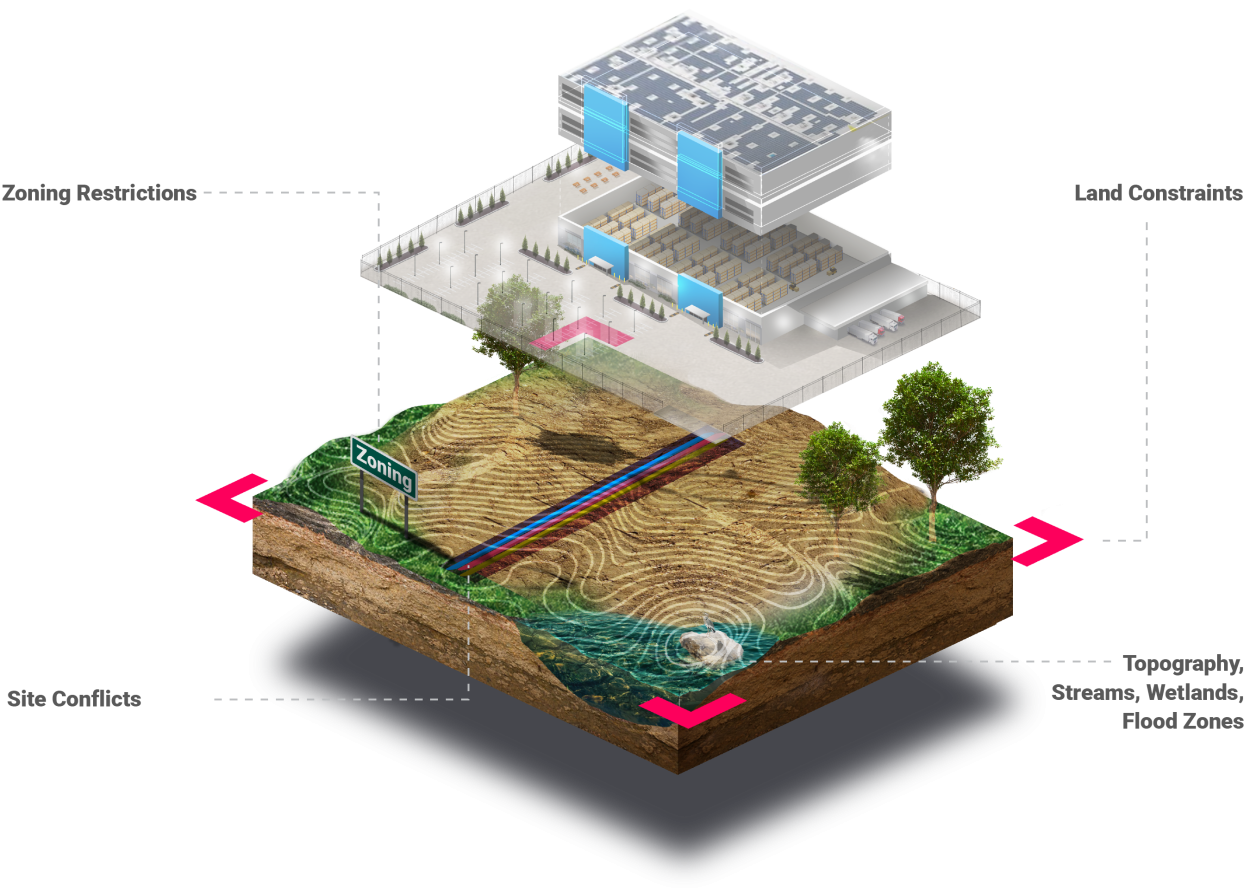

By identifying potential site constraints and challenges early, such as topography, flood zones, or zoning constraints, we can devise strategies with the client to mitigate these risks. Addressing these challenges reduces the likelihood of encountering unexpected problems during permitting and construction. Effective risk mitigation is vital to maintaining project timelines and avoiding costly delays.

Enhanced Collaboration

The test fit process fosters collaboration between civil engineers, architects, and developers. This multidisciplinary approach ensures that all aspects of the project are considered, leading to a more cohesive and well-integrated development plan. Collaboration enhances communication, reduces misunderstandings, and ensures all stakeholders are aligned with project objectives.

Improved Decision Making

A detailed test fit allows developers to make more informed decisions about site selection and project viability. It provides a visual representation and technical data that can be critical in decision-making. Informed decision-making is essential for choosing the best site, avoiding pitfalls, and ensuring project success.

The Bottom Line

By incorporating the test fit process early in the due diligence phase, we help industrial developers create more efficient, compliant, and cost-effective projects. This strategic planning step is crucial for the successful realization of industrial developments. Through careful planning, test fits reduce project risks and lead to more efficient outcomes, saving both time and financial resources.